Some time ago I played with the idea of building a snare drum, but for this reason or that I never tried…until now. With the extra time I have these days, I sat myself down in front of the computer, did my research, ordered my parts and began.

It’s taken me about a week and a half to finish the drum and now I know why custom drum builders charge so much money, it really is hard work. I enjoyed building the drum and my next task is to build a 4 piece drum set.

Picking the wood for drum was difficult and in the end, I ordered German beech wood, it’s a wood normally not used in the states and the wood was inexpensive. No sense in buying say…walnut, especially for my first go at drum building - that may have turned costly.

Below are pictures of my project.

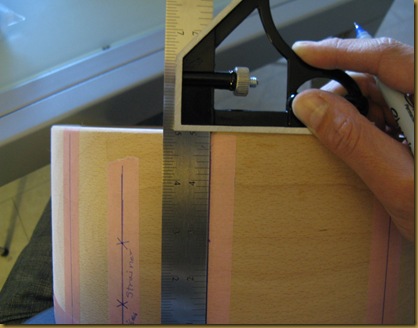

Measuring the distance between the tension rods, using a template.

The tool/square below was the hardest item to find. I went to five different stores searching for this particular square, which by the way was only 5 euros. Drum companies make a drum square which one can buy for about 68 euros.

I also used a snare drum I own (black drum) as a model for my beech drum.

Drilling was the scary part – I really did follow the check three times before you drill rule. Below is a picture of the first hole.

Cleaned the drum removed the tape residue and then I went to work sanding.

Then I had to measure the snare bed. If you want, you can read about snare bed theory here - https://www.drumfoundry.com/driver.aspx?Topic=drum_snare_bed_theory

Having a good snare bed is important for good quality sound. Shaving my drum for the snare bed also made me nervous. As you can see from the picture below, a good chunk of the wood does get removed…so, bad snare bed = bad sound = start again = more money.

Antik – Wachs…this stuff is great. Wood wax for that natural finish.

I still have bruise from holding the drum between my legs. (note to self…self build a stand to hold drum)

And here we have the first wax application and below is the finished product after three coats of waxing and sanding. Check out the matte finish.

Assembly required

After waiting a day for the last wax coating to dry, it was time to assemble my new drum.

Slowly…slowly

Here we have it…My new beech snare drum

I tuned it up, played it bit and at the moment it sounds good, but tomorrow I’m taking the drum into the rehearsal room to replace the factory drum heads with my favorite drum heads and give the drum a true test. I have to also see how it’s going to get along with my drum set. (Orangie can be demanding on snare drums)

The first drum from M&L Drums and hopefully not the last. (by the way I have to work on the badge design…any ideas?)

hugs,

M&L

P.S.

L, is in China for 10 days, so it’s me and Jean-Luc, a bag of catnip and bottle of whiskey.

2 comments:

i like the whole thing - but i especially love the wax - i'm going to wax everything.

what work are you doing at the base?

still miss you guys god dammit!

lynarra

Cats and Whiskey...dangerous combination. Build me a f*#king drum kit you b@$^@%d! And I don't want beechwood...give me maple of give me death...or walnut...or cherry.

Post a Comment